Productivity growth is near historic lows in the United States and much of Western Europe. According to the U.S. labor department, productivity remained sluggish in 2017, manufacturing productivity advanced just 0.7%.

McKinsey estimates that the productivity boosting opportunities could be at least 2% on average per year over the next ten years, with 60% coming from digital opportunities.

Transform or Die

Digital disruption is the main reason why in the past 15 years, 52% of the Fortune 500 companies disappeared.

The average expectancy of a Fortune 500 company has declined from around 75 years half a century ago to less than 15 years today and heading towards 5 years.

Some examples of products now obsolete: maps, land line phones, fax machines, movie rental stores, VCR, phone books, dictionaries, encyclopedias, public pay phones, data floppies or CD’s to back up data.

Organizations that fail to leverage digital to drive innovation, to optimize operations, and to offer their employees an improved and more productive working experience are becoming less competitive.

Digital Leaders vs. Digital Laggards

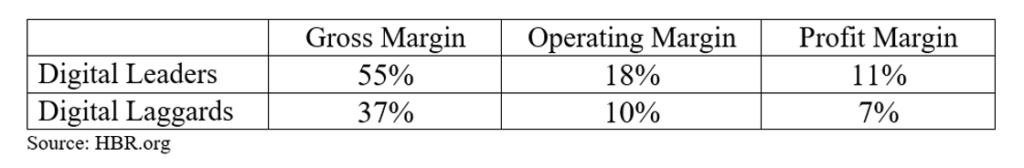

There is quite a difference between digital leaders and digital laggards when it comes to key financial metrics:

The McKinsey Global Institute has calculated that Europe overall operates at only 12% of digital potential and the United States at 18%, with large sectors lagging in both. Technology adoption is lagging, especially in the manufacturing sector:

- 30% have yet to pilot or about to start piloting

- 41% still piloting

- 29% deploying at scale

Benefits of Industry 4.0

Implementation of digital manufacturing has the potential to deliver enormous benefits such as less downtime, fewer defects, improved inventory and overall equipment effectiveness, reduced energy use.

There is optimism about what digital will do for the economy and society. There is a $100 trillion opportunity for industry and society by 2025. Workers are optimistic, five to one think digital will improve their job prospects; ten to one think digital will improve their work experiences.

Industry 4.0 technologies or digital transformation allow companies to stay competitive, increase revenue, speed and transparency; improve productivity, quality, and safety. Technologies such as augmented reality help with the challenging process of knowledge transfer during times of high natural attrition. The required agility depends on a highly skilled workforce.

There are plenty of reasons for manufacturing operations to get started in the digital transformation journey. As an executive coach and business consultant, I help leaders and organizations navigate through an unprecedented amount of complexity and speed of change – develop strategies to ensure human readiness and be successful in the process of digital transformation.